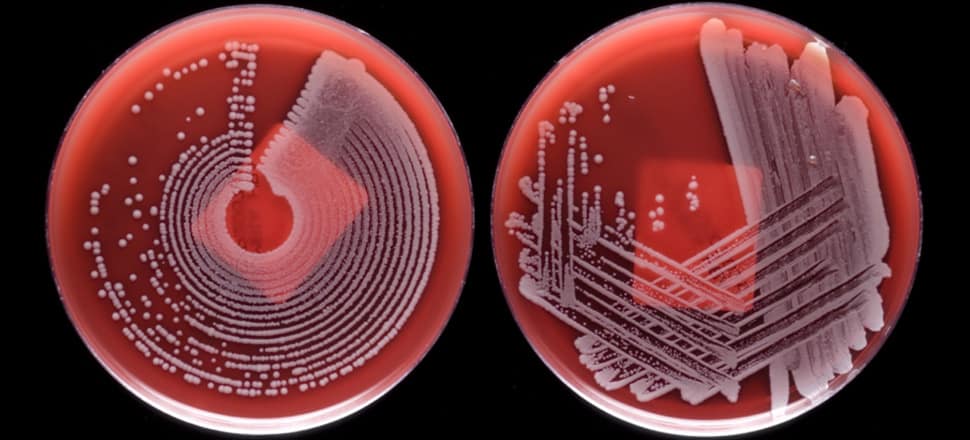

Conventional clinical microbiology involves specimen collection, registration, inoculation, isolation, identification and testing of pathogenic microbes from clinical specimens. Traditionally, this process has used minimal automation. The isolation of bacterial colonies for identification and antibiotic susceptibility testing is performed manually using handheld spreading devices called “loops” to streak a specimen onto one or more agar plates for incubation. This process is highly labor intensive, produces results of variable quality, and ties up highly skilled and valuable microbiologists by performing routine work in an environment where their skills are in increasing demand.

LabTech Systems developed a revolutionary concept for mechanically streaking microbiological specimens on to conventional agar plates for diagnostic microbiology.

They approached us to develop a concept for high-throughput automation of this core process in clinical laboratories, and then to design and manufacture this instrument.

The technical challenge required us to design a highly robust system to deal with a very wide variety of sample types at high throughput while handling a wide range of agar plate types at high speed and producing reliable and consistent plate streaking.

Our team worked closely with LabTech Systems, and later with bioMérieux, to build on their critical market input to design, develop and manufacture the instrument. The goal was for it to use LabTech’s innovation to automate many of the manual tasks traditionally involved in the preparation of agar plates.