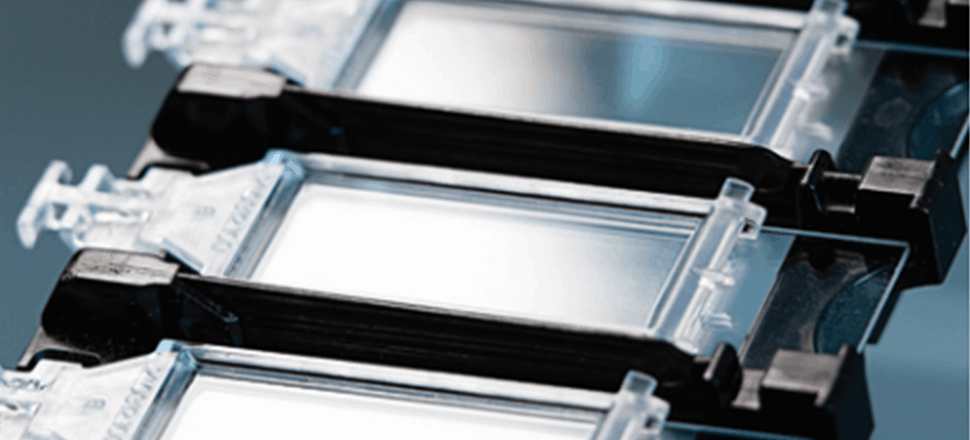

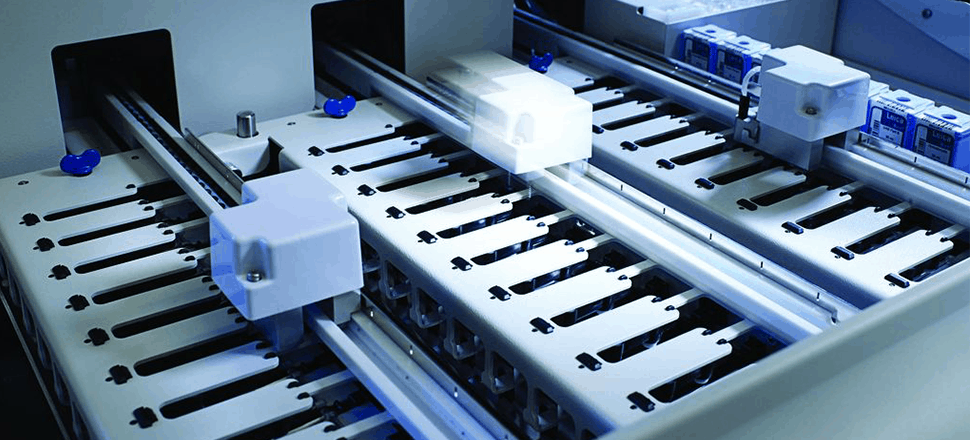

We have now developed three generations of the Bond tissue staining platform, the most recent iteration being the Leica Biosystems BOND-III, a fully automated immunohistochemistry (IHC) and in-situ hybridization (ISH) staining system that improves speed, efficiency and quality to histopathology laboratories and hospitals throughout the world.

We developed the original BOND platform for our sister company, Vision Biosystems. Now known as Leica Biosystems, this staining platform has experienced considerable commercial success with more than 5,000 placements worldwide across the three product generations. The BOND instrument family has become the backbone of Leica Biosystem’s business and has enabled them to expand to supply about one-third of the histology market.

The Leica BOND-III instrument enables laboratories to meet increasing workloads using existing resources, allowing laboratories to save time, and ultimately, reduce cost.