In case you missed it, Invetech recently sponsored a webinar hosted by the International Society for Cellular Therapy (ISCT) focused on the key considerations for achieving commercial success for cell therapies.

The webinar featured presentations by Mike Paglia, senior director of technical operations at bluebird bio, who shared his insights on needle-to-needle logistics, as well as Mark Curtis, business development analyst at the Centre for Commercialization of Regenerative Medicine (CCRM), who discussed new ways of looking at the reimbursement landscape when bringing a therapy to market (read Mark’s recap here).

Richard Grant, Global Vice President of Cell Therapy at Invetech, focused on the importance of manufacturability, as well as ways to minimize cost of goods while still maintaining product quality. Below is a brief recap of the key points from Richard’s presentation. You can also watch the webinar recording in its entirety here.

Cell therapies show incredible promise for treating some of today’s most debilitating diseases. As a new therapy emerges, cell therapy companies must focus on efficacy—making sure the treatment is safe and effective for patients. But as they progress through clinical trials and move closer to commercial-scale production, the focus must shift to scalability, reproducibility and integrity of the product throughout the supply chain.

Cell therapies show incredible promise for treating some of today’s most debilitating diseases. As a new therapy emerges, cell therapy companies must focus on efficacy—making sure the treatment is safe and effective for patients. But as they progress through clinical trials and move closer to commercial-scale production, the focus must shift to scalability, reproducibility and integrity of the product throughout the supply chain.

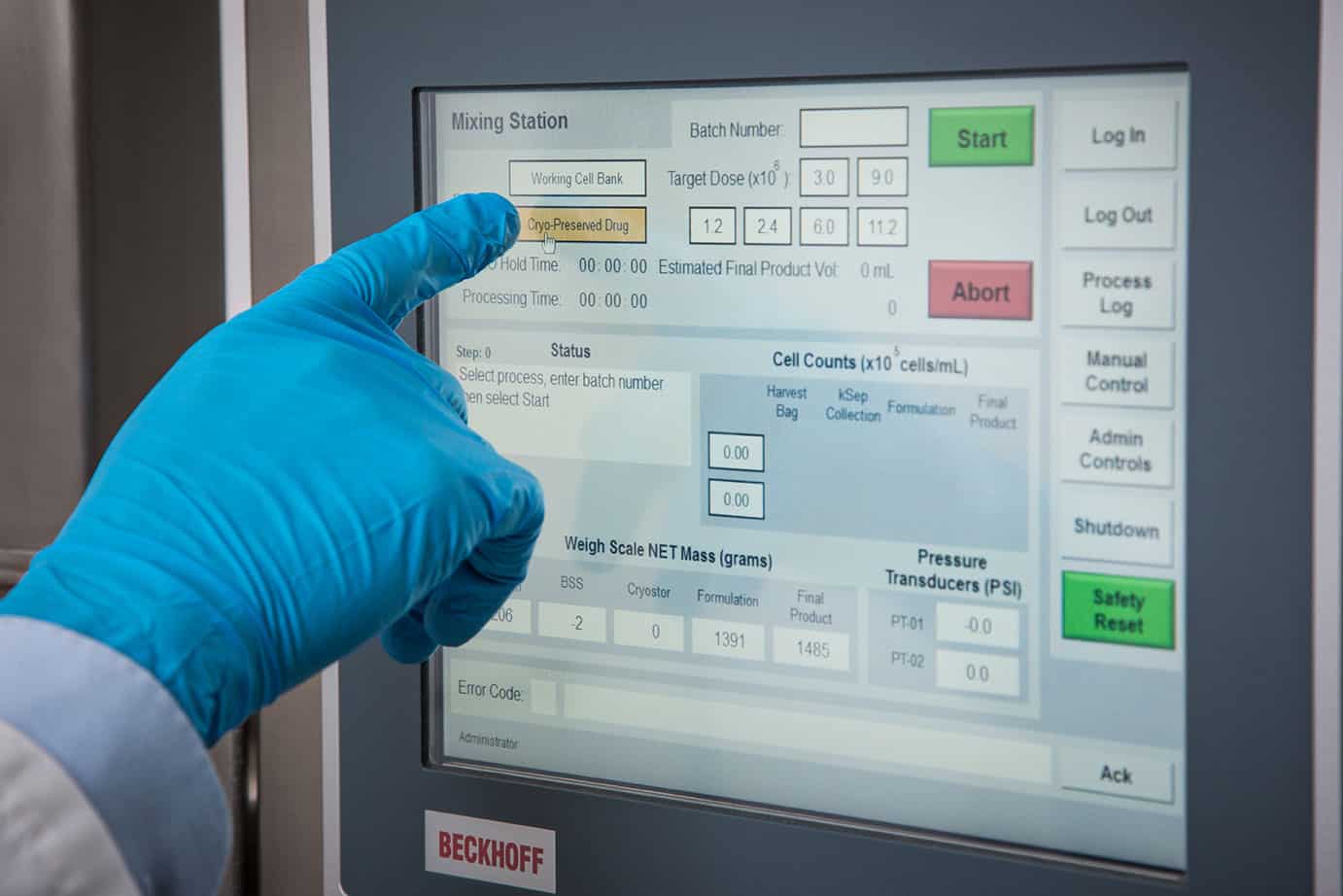

Human error or variability is a primary cause of inconsistency, disruption and loss in a manufacturing process. Rigorous QA processes can help reduce the risk of quality-related loss and exposure to criticism or restrictions in the industry, while automation can eliminate human error and variability within the process. Employing tactics like automated sequencing, error-proofing consumable loading, and controlled QC collection also help to keep quality levels high.

Human error or variability is a primary cause of inconsistency, disruption and loss in a manufacturing process. Rigorous QA processes can help reduce the risk of quality-related loss and exposure to criticism or restrictions in the industry, while automation can eliminate human error and variability within the process. Employing tactics like automated sequencing, error-proofing consumable loading, and controlled QC collection also help to keep quality levels high. In the healthcare industry, patients and practitioners must have complete confidence that the treatment they’re administrating is safe and not contaminated. There are several keys to ensure this as you scale manufacturing:

In the healthcare industry, patients and practitioners must have complete confidence that the treatment they’re administrating is safe and not contaminated. There are several keys to ensure this as you scale manufacturing: Lower COGS by optimizing processes through use of single-use disposables, minimizing skilled labor through automation, and reagent and quality testing optimization.

Lower COGS by optimizing processes through use of single-use disposables, minimizing skilled labor through automation, and reagent and quality testing optimization.